Moscow – Researchers at the Skolkovo Institute of Science and Technology (Skoltech) are developing a revolutionary in-situ conversion technology that could fundamentally change the extraction of hydrocarbons from low-maturity shale, potentially unlocking the massive energy potential of formations like the Bazhenov Suite. The technology, known as Supercritical Water Kerogen Conversion (SWKC), artificially accelerates a natural geological process that takes millions of years, compressing it into a matter of hours or days.

The Science of Acceleration: Harnessing Supercritical Water

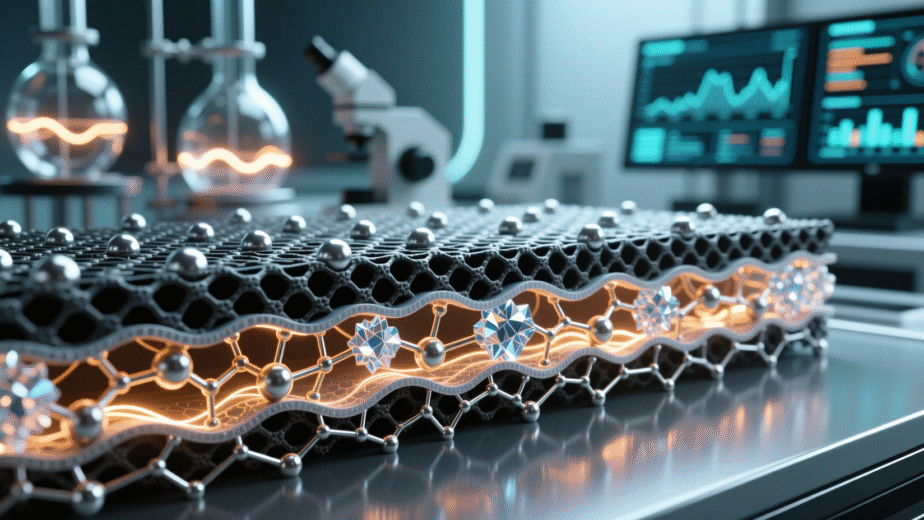

The core of the SWKC technology involves the use of supercritical water—water heated to temperatures between 350–380°C under extremely high pressure of 200–300 atmospheres. In this state, water exhibits unique properties: it behaves like a powerful solvent with high diffusivity, allowing it to penetrate deep into dense shale rock matrices that are otherwise impermeable.

Once inside the rock, supercritical water initiates a chemical reaction that breaks down the complex macromolecular structure of solid kerogen—the organic matter found in shale—into lighter, liquid hydrocarbons, effectively generating synthetic oil underground. This process not only creates new oil but also enhances extraction by generating numerous nanopores within the rock, significantly increasing its porosity and permeability.

A Leap in Efficiency: Superior to Conventional Methods

The SWKC technology represents a significant advancement over traditional methods like anhydrous pyrolysis or steam injection. Research into supercritical water conversion has demonstrated its clear advantages:

-

Higher Yields: Experiments on low-maturity shale have shown that supercritical water conversion can achieve higher oil yields at lower temperatures compared to conventional pyrolysis. For instance, one study recorded an optimal oil yield of 352.1 milligrams per gram of Total Organic Carbon (TOC) at 380°C, surpassing yields from traditional methods at the same temperature.

-

Faster Reactions: Molecular-level simulations reveal that supercritical water actively participates in the chemical reactions, lowering the activation energy required for kerogen degradation by 2–18 kcal/mol and reducing degradation temperatures by 60–160 Kelvin. This translates to a much faster and more energy-efficient conversion process.

-

Reduced Environmental Impact: The technology utilizes water as its primary agent and can convert organic matter into usable fuels without leaving behind heavy organic digestate, aligning with cleaner production goals.

Engineering a Subsurface Refinery: The Proposed Extraction Method

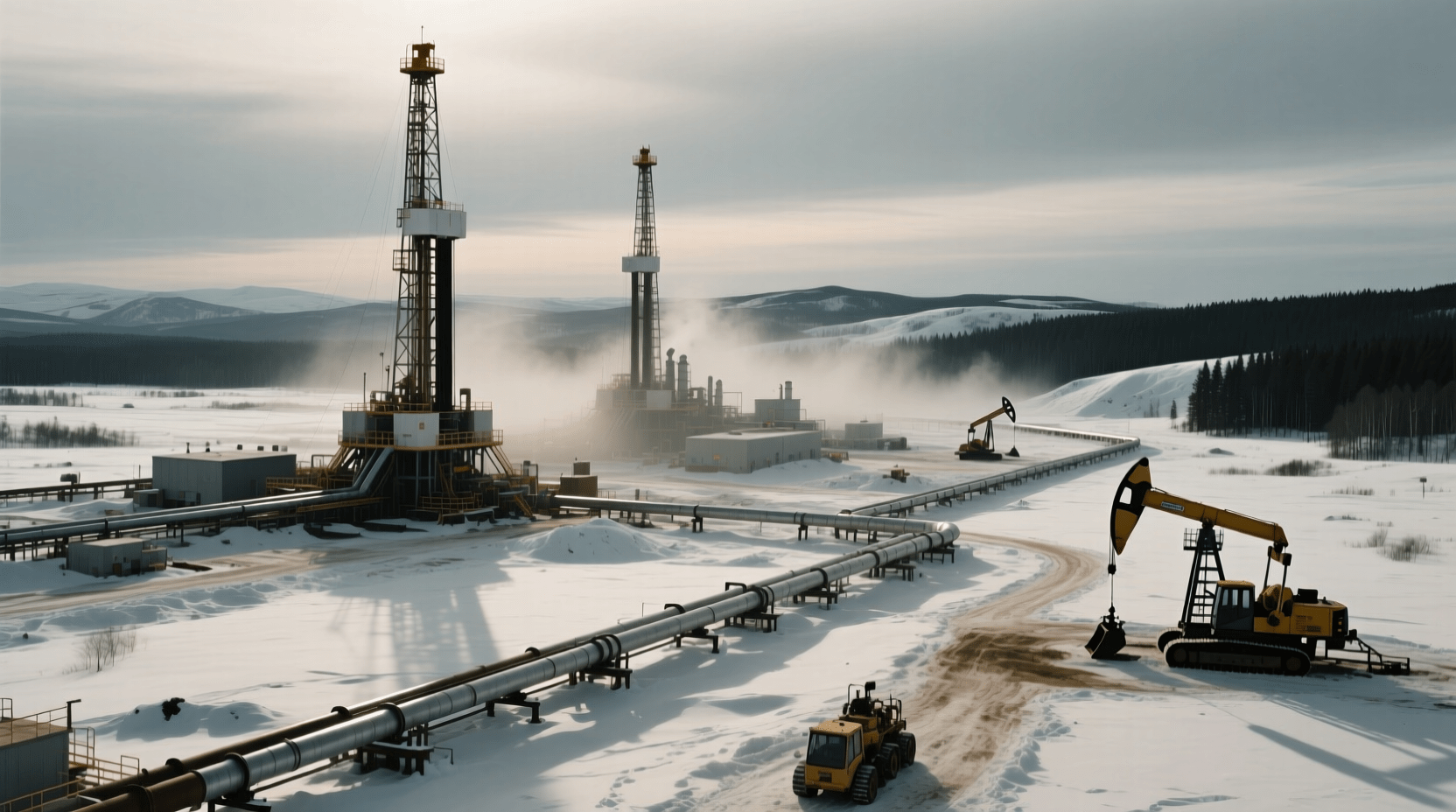

To implement this technology in the field, Skoltech researchers propose an engineered system involving two parallel horizontal wells drilled into the target shale formation. Supercritical water is pumped down into the rock through the first well, creating a reaction zone where kerogen is converted into oil. The newly formed synthetic oil is then driven toward and extracted from the second well, creating a controlled and continuous production process.

Leadership and Global Context

The development at Skoltech is led by Elena Dmitrievna Mukhina, a leading researcher at the Skoltech Center for Hydrocarbon Extraction Science and Technology. As the first author of the key scientific publication and the main expert on the project, she heads a team that is pushing the boundaries of hydrocarbon science. Their work is part of a broader global effort to develop in-situ supercritical water conversion for hard-to-reach resources, with significant parallel research being conducted in China and other countries.

This innovation positions Russia at the forefront of next-generation oil extraction technologies, offering a potential pathway to sustainably develop its vast shale oil reserves, enhance national energy security, and foster new avenues for international scientific collaboration.