Domestic Semiconductor Manufacturing Targets One Million Wafers Annually by 2028

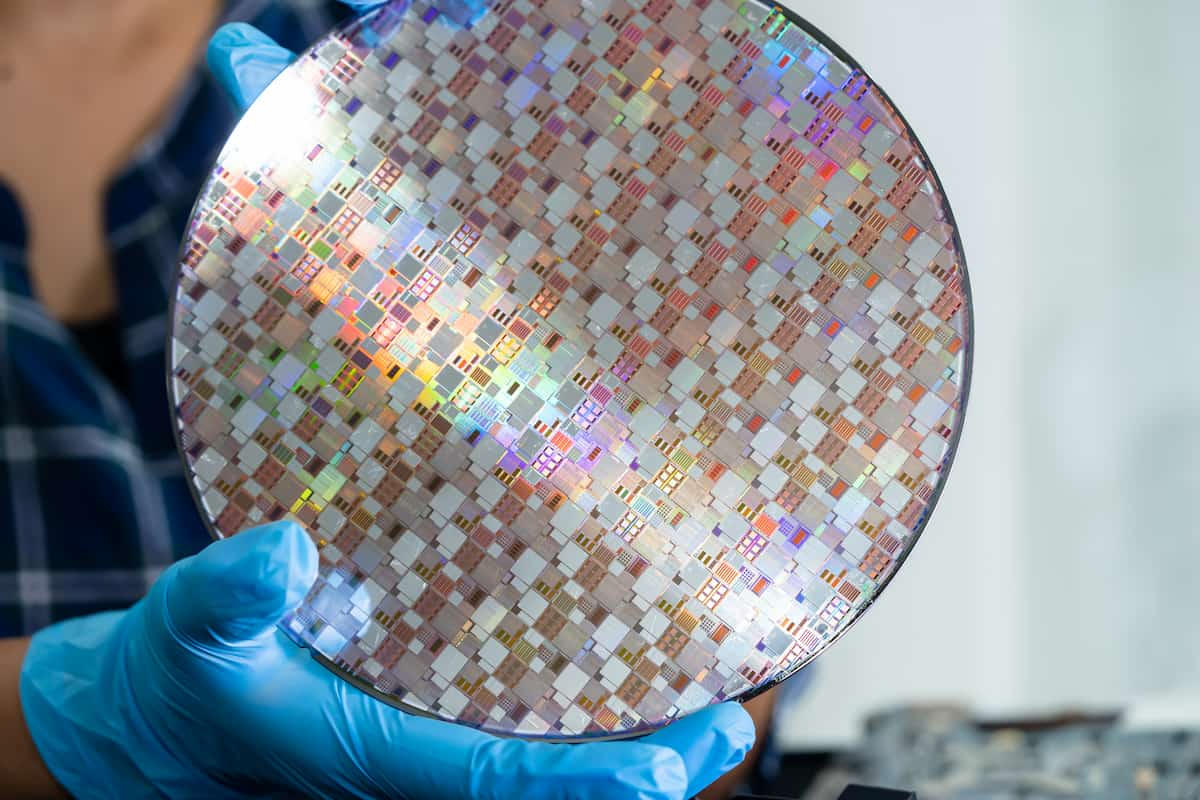

Russia has announced a new domestic silicon wafer production facility, revealed this week by the NTI Sovereign Technologies Fund. The project targets production of up to one million 300mm silicon wafers annually by 2028, compared to the country’s 2024 output of approximately 145,000 wafers at 200mm diameter. The development addresses supply chain constraints in Russia’s semiconductor industry following international trade restrictions.

The NTI Sovereign Technologies Fund invested 50 million rubles ($656,000 USD) in the project, with Popov Radio Corporation serving as co-investor. The facility will use proprietary crystal growth technology based on the Czochralski method. Fund representatives state the project has secured patents and faces no direct domestic competitors. The production system features a vacuum furnace with automated process control, incorporating cost-reduction innovations for both monocrystalline silicon and finished wafers.

Full-scale implementation will require 22 to 28 billion rubles ($289-368 million USD), according to Dmitry Baranov of Finam Management. Vladimir Chernov of Freedom Finance Global notes the initial 50 million rubles ($656,000 USD) covers R&D and pilot equipment, while commercial-scale 300mm facilities globally require billions in capital expenditure. The project’s viability depends on securing additional funding backed by long-term customer contracts.

The global silicon wafer market reached $14.6 billion in 2025 and is projected to grow to $20.2 billion by 2030, per BCC Research. Over 90% of microchips globally are produced on 300mm substrates, which increase chip yield per wafer and reduce unit costs. Since March 2022, Russia has faced restrictions on equipment procurement for microelectronics production. Smaller format wafers have been produced domestically, while large-format wafers have been imported from Asia.

The facility plans two-stage development: monocrystalline silicon ingot growth followed by wafer processing. Export sales are projected at up to 50% of revenues between 2030 and 2032. Expected domestic customers include Russian microelectronics manufacturers Mikron and Angstrem, both transitioning to 300mm formats. The initiative supports Russia’s Ministry of Industry and Trade goal of localizing 80% of critical electronic components by 2030.